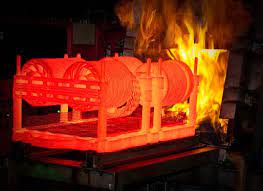

Traitements thermiques

Heat treatment is a process of heating and cooling metals to alter their physical and mechanical properties, such as hardness, toughness, ductility, and strength. Quenching, tempering, and annealing are three common types of heat treatment techniques used in the metallurgical industry.

Quenching involves rapidly cooling the metal from a high temperature to room temperature, typically by immersing it in water or oil. This process hardens the metal by creating a martensitic structure that is strong but brittle. Quenching is commonly used to harden high carbon steel, alloy steel, and tool steel.

Tempering is a process of reheating the quenched metal to a temperature below its melting point and holding it there for a specific period. The reheating process reduces the brittleness of the metal and increases its toughness and ductility. The temperature and duration of the tempering process determine the final properties of the metal. Tempering is commonly used to improve the properties of hardened steels.

Annealing is a process of heating the metal to a specific temperature and then cooling it slowly to room temperature. This process softens the metal, making it more ductile and less brittle. Annealing is commonly used to relieve stress, improve machinability, and enhance the electrical and magnetic properties of metals.

In summary, quenching, tempering, and annealing are essential heat treatment techniques used in the metallurgical industry to alter the physical and mechanical properties of metals. Understanding these processes and their applications is crucial for engineers, metallurgists, and anyone involved in the production, fabrication, or maintenance of metal components.